Edge Consulting Engineers had a new customer for 2022 request an inspection on their large scale solar farm. Edge inspected 2 of their solar PV systems with 400 acres per site. These solar farms provide 50MW per site, which is enough to power 13,000 homes annually.

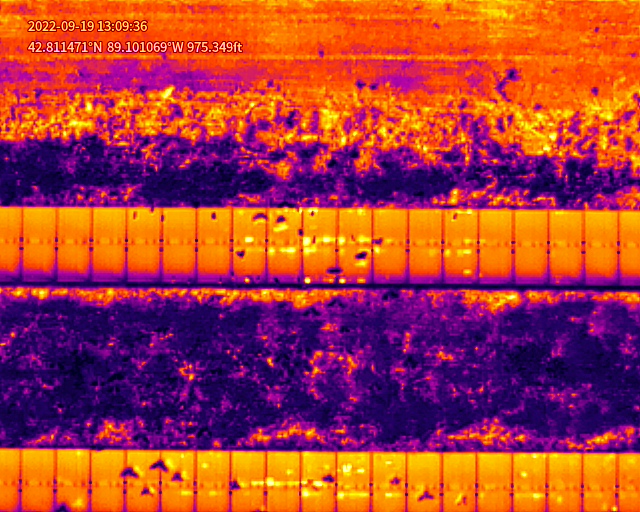

The purpose of these inspections was to find issues with the solar panels prior to the site being brought into full operation. Damaged or defective solar panels could knock a full string (group of panels linked together) out of operation. To complete an inspection on this site Edge reviewed between 40,000 to 50,000 images per site. Things that had to be checked in this inspection was the temperature of the panels, to ensure that they were all running at a consistent temperature. Also looking for any defects or faults in the panels.

This inspection work was completed utilizing drones with thermal capabilities as well as high resolution cameras. Completing the work with handheld scanning devices would have been nearly impossible given the size of this solar farm. UAS technology made the process much easier and more cost effective. While flying the drones we were able to take pictures with all three lenses; thermal, standard, and angled. In addition, we were able to obtain zoomed images of every specific panel. This helped the client pinpoint issues and visually inspect panels remotely. UAS also allowed us to provide our client with the exact panel ids with issues, making the correction process much easier.